- History & Definition

- Consituents of Printing Ink

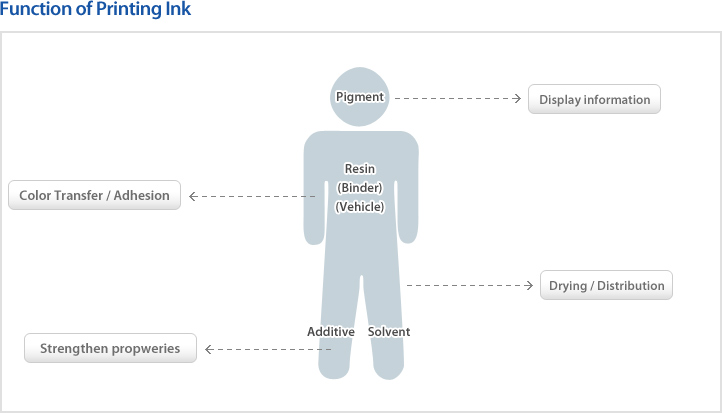

- Function of Printing Ink

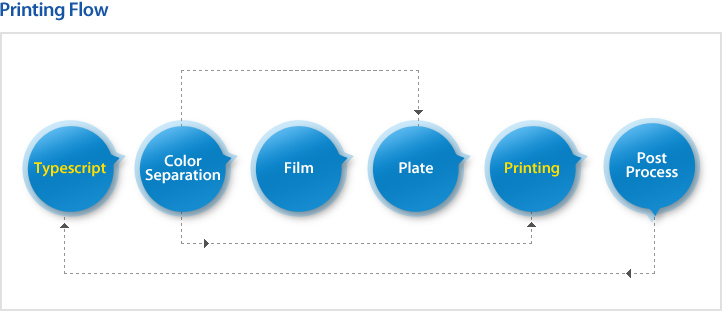

- Printing Flow

Printing ink was invented in China along with the discovery of printing technology in ancient China.

Chinese ink was not same liquid consistency as it is today but, instead, was more of a writing stick which foreigners call India ink. This was developed in 220~419 A.D. during the Jin Dynasty or Huhan Dynasty.

Printing ink is made up of pigments that give color and varnishes that enhance color. In ancient China, ink pigments were made from the smoke produced from the incomplete combustion of Japanese hemlock and various oils in a vessel.

The only difference from modern day ink is the constituents making up the varnish.

Varnishes used in ancient times were made from the glue produced from boiling animal bones or leather. This water based substance was dissolved in water and mixed with pigments in stone or steel mortar and became jelly when hardened.

During the Soo Dynasty in 6th century China, wood plate printing was invented and books were produced since that time using the same method of spreading the jelly over an engraved wood plate, placing paper over the plate then pressing over the paper.

The invention of printing undoubtedly increased the use of ink. As a result, ink manufacturing became a first rate major technology and ink technicians came to earn high respect.

During about 712 A.D., the notorious Emperor Hyunjong contributed an ink of his own creation to a university and skilled technicians developed secret formulae for each of the various inks.

Various methods were applied such as making special glue from deer antlers and mixing in egg whites or musk scents.

Much time has since passed, however, and the world has come to a new era where printing ink is undergoing change.

Non polluting, energy saving, resource reducing problems are being combated with the development of new types of ink such as UV inks that harden instantly with exposure to UV rays, various water based inks that incorporate new functionality, and LTD inks for low temperatures.

The definition of “printing” in a printing glossary is as follows.

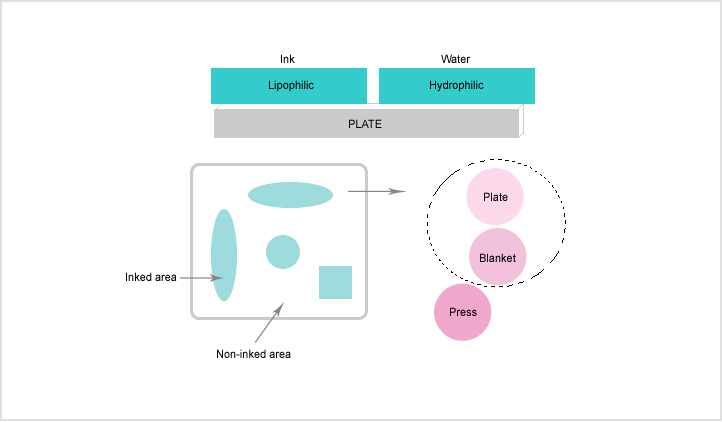

< The technology of making individual plates customized for each typescript, spreading ink over these plates then applying pressure over the inked areas to transfer the ink onto large quantities of paper or other surfaces. >

These 5 items mentioned above, "typescript", "plate", "ink", "pressure (pressure from the printing machine)", "paper or other surface”, are called the < 5 essential factors of printing >.

This definition applies to printing ink and is completely different, functionally and fundamentally, from writing ink. The composition of printing ink is more similar to oil paint or oil colors but contrarily to paints or dyes, which are applied directly onto the surface using , brush or spray, printing ink consists of a more complex process of going through a printing machine, plate and blanket before actually being printed onto a surface. Another major difference is that considerably thinner films of printing inks are used

in comparison to paint or dyes.

Whereas paint is applied to protect the substrate and to enhance its appearance and dyes are applied for artistic creation, the main purpose of printing ink is to reproduce mass quantities of different typescript. Accordingly, the 5 essential factors and their

interconnected factors need to be regulated and the proper preparation of printed matter should not be neglected.

The 3 basic constituents of printing ink are colorant (industrial pigment), vehicle and additive (builder) and are developed from the raw materials classified as follows.